INNOVATION

We have a history of developing ground-breaking products:

- In 1928, fiber lines were installed in the Motus facilities that now produce fiber product

- In 1966, injection molding assets were deployed in the Motus facilities that now produce interior trim

- In 1997, we introduced the first headliner with head impact components

- In 2000, we developed the first glass-free headliner

- In 2005, the first of 2 Mexico facilities was established to wrap interior trim

- In 2006, we introduced 1-Step Edgefold for thermoplastic headliners

- In 2008, we produced an acoustic polybond headliner

- In 2009, the first fiber trunk system was introduced

- In 2010, we developed pinch seal polypropylene glass headliners

- In 2011, we were awarded the simulated stitch armrest patent

- In 2013, we introduced 1-Step Edgefold for thermoset headliners

- In 2015, we introduced our first fiber wheel liner

MANUFACTURING

We design and engineer our products to your needs, supporting you from concept to launch with global manufacturing resources. We share best practices and standardize processes across our facilities, ensuring the same high quality to OEMs all over the world.

THERMOPLASTIC FORMING SIMULATION

This industry exclusive forming simulation reduces tooling and start-up costs by fine-tuning surface and process requirements prior to tool release. Our team has the ability to simulate multiple surface conditions early in the design process.

SOFT TRIM SIMULATED STITCH

The Company’s proprietary faux stitching technology has historically been utilized to enhance the aesthetic of the armrests and consoles. This design provides a more cost effective stitch design.

Motus is now in the process of modifying the technology in order to expand to alternative, higher-end applications. This new process will allow for reduced material and a more premium feel and look.

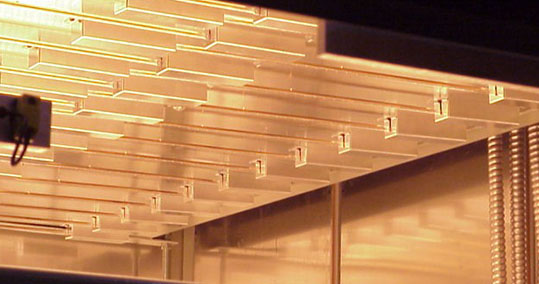

PET NATURAL FIBER HEADLINER

This innovative headliner provides:

- The use of a PET fiber mat that is fully recyclable.

- Excellent acoustic absorption performance.

- Current Thermoset process capital processing equipment.

COMPRESSION FORMING

We offer premier manufacturing capabilities in multiple compression-forming technologies:

- Thermoplastic Dry PU & PP/Glass

- Thermoplastic Fiber

- Thermoset Wet PU

From design to production to delivery, we help reduce launch time and costs through highly developed technical tools. Our robust launch process includes:

- Highly controlled monitoring

- Industry-leading tolerancing

- Edge treatment options

– Edgefolding

– Edgewrapping

– In-tool trimming

INTERIOR TRIM MANUFACTURING

We offer technologies to produce our armrests and interior trim components through several manufacturing methods:

- Hand Wrap, Cut and Sew

- Vac-Forming

- Negative Vac-Forming

- Bladder Forming

- CNC Cutting

- Automatic Wrapping

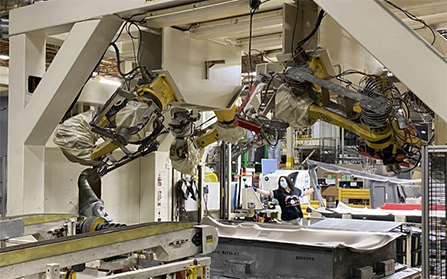

OVERHEAD SYSTEM ASSEMBLY

Our overhead system assembly capabilities range from manual operations to high levels of automation. We offer flexible assembly capabilities with the ability to scale our equipment to meet customers’ needs.

ENVIRONMENTAL TESTING CAPABILITIES

ACOUSTIC PERFORMANCE TESTING

Capabilities include:

- Alpha cabin testing

- Impedance tube testing

- Gas permeameter (air flow)

ENVIRONMENTAL TESTING CAPABILITIES

- Russells environmental walk-in chamber

- Environmental reach-in chamber

- Air oven