Design and Production Innovation

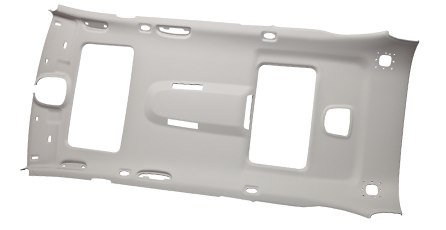

At Motus, we have one of the broadest and most technologically advanced headliner portfolios in the market. We can meet any performance need for weight, mass, acoustics, strength and stiffness.

Meticulous craftsmanship and advanced production processes create forward-leaning headliners and automotive interiors that deliver enhanced usability and reliability. Even our tools are unique: they allow us to predict engineering issues, prevent future manufacturing problems and help reduce overall costs before production so customers can refine their designs and eliminate issues before they occur.

The perfect balance between beautiful design and strength add a whole new dimension to what an interior can be.

Our headliners are engineered to achieve strength, stiffness and acoustic absorption performance requirements at the lowest possible mass, thickness and cost.

Our lightweight compression formed fiber products provide acoustical and insulation solutions while providing reduced weight and recyclability.

At Motus, we have one of the broadest and most technologically advanced headliner portfolios in the market. We can meet any performance need for weight, mass, acoustics, strength and stiffness.

Motus produces a full portfolio of armrests, consoles, instrument panel trim and soft trim components with superior styling and expert craftsmanship and performance.

Motus is committed to responsible corporate citizenry, using more than a century of experience in the manufacture of recycled materials to develop environmentally friendly fiber solutions. Starting with recycled post-industrial natural fiber from sources such as scrap denim, and synthetic fibers made from post-consumer waste from plastic bottles and other sources, Motus creates thermal and acoustical trim products used both inside and outside the vehicle.